ODM/OEM Services

Original Design Manufacturing (ODM) and Original Equipment Manufacturing (OEM) services have emerged as pivotal strategies for businesses looking to streamline their operations, reduce costs, and bring high-quality products to market swiftly.

Products We Design

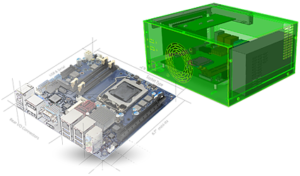

We design high-quality and long lifecycle industrial motherboards and embedded computing solutions.

Types of Custom Design

we are experts at custom designing computer-based products.

ODM Custom Design Process

We design quality and extended-lifecycle industrial motherboards and embedded computing systems.

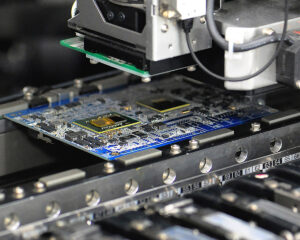

MUJO Production Services

Manufacturing as a service: everything from assembly and localization to branding and integration of equipment into work complexes

Our Advantages

Products We Design

In the dynamic landscape of today’s business environment, companies are constantly seeking innovative ways to stay ahead of the competition. Original Design Manufacturing (ODM) and Original Equipment Manufacturing (OEM) services have emerged as pivotal strategies for businesses looking to streamline their operations, reduce costs, and bring high-quality products to market swiftly.

Types of Custom Design

we are experts at custom designing computer-based products. Whether our customers are looking for a modified standard product, or a full turn-key custom design starting from a concept, we have the expertise and the capabilities to deliver a design that meets the specification, speeds time-to-market. In each of these areas, custom design is essential for meeting the unique needs and preferences of clients, customers, or end-users.

ODM Custom Design Process

New Project Initiation & Evaluation:

The process begins with an in-depth discussion between the client and the ODM provider. During this stage, the client outlines their product requirements, specifications, design preferences, target market, and any unique features they want to incorporate.

Based on the client’s requirements and the findings from market research, the ODM provider creates a conceptual design proposal. This proposal includes an overview of the product, design sketches, and an outline of key features. It serves as a starting point for discussions and refinement.

Product Design & Development:

This phase commences following a signed-off Requirements Document. During this phase we will create a Functional Test Plan, provide a product ID design, develop schematics, create mechanical drawings, and begin tooling for mechanical parts, layout the CPU board and create Gerber files, and identify key components for the MUJO.The client provides feedback on the initial design proposal, and the ODM provider refines the design accordingly. This iterative process continues until the client is satisfied with the proposed design. Once approved, the design moves to the next stage.

With an approved concept, the ODM provider develops detailed design specifications, including engineering drawings, schematics, and material specifications. The goal is to create a comprehensive blueprint that guides the manufacturing process.

Prototype & Validation:

A prototype of the custom-designed product is created based on the detailed specifications. Prototyping allows both the client and the ODM provider to physically assess the design, test functionality, and identify any potential issues before mass production.

During this phase we will provide a progression of pre-production prototypes for core functionality testing, application testing, proof of concept, compliance testing, and customer demonstration purposes.

PILOT Run:

PILOT Run:

Following completion of the design verification testing and any final updates are approved and implemented, a pilot run will commence for production level units in quantities typically ranging from 25 to 200 units. During this phase our factory production engineers (PE) will finalize their manufacturing SOP and perform in-depth QA/QC verification.

Production release:

Production release:

It involves final review and verification of the product(s) and production release documentation. Responsibility will transfer from the project management team to the manufacturing operations team. The prototype undergoes rigorous testing to ensure it meets quality standards, complies with regulations, and functions as intended. Testing may include performance testing, stress testing, and reliability testing. Client feedback during this stage is crucial for final refinements.

Product Life Cycle Management:

Product Life Cycle Management:

At MUJO our business is anchored around keeping a product available for as long as possible. That is why we thoroughly review our component selection prior to adding them to our approved vendor list (AVL). Mujo is committed to bring reliable products to our customers as long as demand and parts are available. The ODM provider may offer post-production support, including warranty services, maintenance, and any necessary product updates. This ensures ongoing customer satisfaction and addresses any issues that may arise after product launch.

Our Strengths

With almost three decades of OEM/ODM computing design and manufacturing experience, our success as an ODM partner is evident in the companies we do business with and our track record of repeatedly winning new designs within those companies. The strengths we bring to the ODM customer relationships include: